Introduction

In today’s fast-paced manufacturing landscape, efficiency is key to staying competitive. Automatic wire cutting and stripping machines have emerged as game-changers in the industry, offering a variety of advantages that streamline operations and maximize productivity. Let’s deep dive into how these innovative machines can transform efficiency and production in your factory.

1. Precision and Accuracy

Automatic wire-cutting stripping machines are equipped with advanced technology that ensures precise and accurate cutting and stripping of wires every time. By automating these tasks, manufacturers can eliminate human error and achieve consistent results with every operation. This level of precision minimizes material wastage and reduces the need for rework, ultimately saving time and resources.

2.Speed and Throughput

One of the most significant advantages of automatic wire cutting stripping machines is their impressive speed and throughput capabilities. These machines can process wires at high speeds, significantly increasing production rates compared to manual methods. With faster cycle times, manufacturers can fulfill orders more quickly and meet tight deadlines without compromising on quality.

3. Versatility and Flexibility

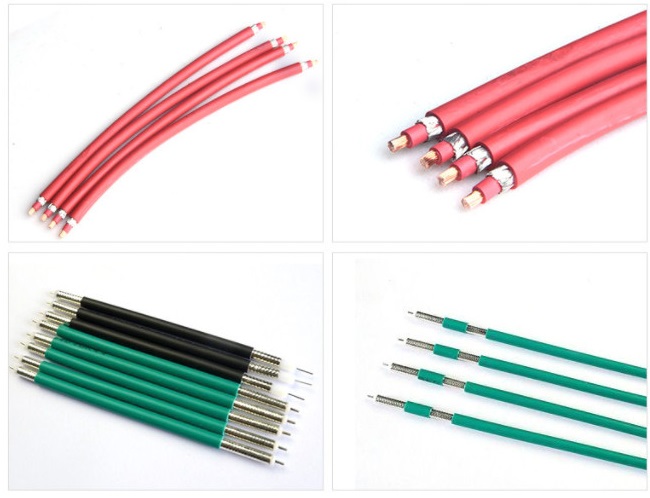

Modern automatic wire cutting stripping machines offer a high degree of versatility, allowing them to handle various wire types, sizes, and configurations. Whether it’s single-core or multi-core cables, thin or thick wires, these machines can adapt to different requirements with ease. Additionally, they can perform a range of cutting and stripping operations, including partial stripping, multi-step stripping, and jacket removal, providing flexibility to accommodate diverse production needs.

4. Improved Safety

Safety is paramount in any manufacturing environment, and automatic wire cutting stripping machines are designed with built-in safety features to protect operators from potential hazards. With automated operations, workers are less exposed to sharp cutting blades and hazardous materials, reducing the risk of accidents and injuries. Furthermore, these machines adhere to strict safety standards and regulations, ensuring a secure working environment for all personnel.

5. Enhanced Ergonomics

Manual wire cutting and stripping can be labor-intensive tasks that lead to operator fatigue and repetitive strain injuries over time. Automatic wire cutting stripping machines alleviate these concerns by taking over the manual workload. Operators can oversee the production process from a safe distance, minimizing physical strain and discomfort. This improved ergonomics not only enhances worker well-being but also boosts overall morale and productivity.

In conclusion, automatic wire cutting stripping machines are revolutionizing efficiency in the manufacturing sector by offering precision, speed, versatility, safety, ergonomics, and connectivity. As technology continues to advance, these machines will play an increasingly vital role in driving productivity and profitability for businesses worldwide. Embracing automation is not just a choice but a necessity for staying ahead in today’s dynamic market landscape.

Check out our best-in-class wire cutting, stripping and twisting machines below:

Why Choose TKS Industries?

Innovation: TKS Industries leads in wire processing innovation, incorporating the latest technological advancements for superior cutting and stripping performance.

Reliability: Our Wire Cutting and Stripping Machines are well known for reliability. Built for consistency, they ensure the integrity of your wire products.

Custom Solutions: Benefit from our ability to provide tailored wire cutting and stripping solutions, meeting the unique requirements of your wire processing operations.

Elevate your wire processing efficiency with TKS Industries’ Wire Cutting and Stripping Machines. Contact us today to explore how our advanced technology can enhance the precision and speed of your wire cutting and stripping operations.